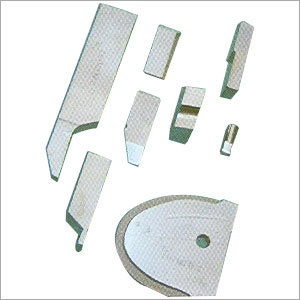

सबसे लोकप्रिय उत्पाद

फà¥à¤°à¥à¤® à¤à¤à¤°

फà¥à¤°à¥à¤® à¤à¤à¤° Specification

- ड्रिल बिट्स के प्रकार

- Form Drill Bit

- ऑपरेशन का प्रकार

- मशीन का प्रकार

- CNC Milling Machine

- काटने की क्षमता

- Up to 10 mm thickness

- कटिंग फोर्स

- Low to Moderate

- लम्बाई

- 90 mm

- प्रचालन विधि

- Manual & Automated

- मटेरियल

- काटने की सटीकता

- ±0.01 mm

- टूल टाइप

- Form Cutter

- कोटिंग का प्रकार

- Single Layer Coating

- कटिंग स्पीड

- 80-120 m/min

- विशेषताएँ

- High precision, Abrasion Resistant, Smooth Finish

- कटर का प्रकार

- Profile/Form Cutter

- लेप करना

- Titanium Nitride (TiN)

- कठोरता

- HRC 55-60

- शेप

- Cylindrical Form

- व्यास

- 16 mm

- अधिकतम टॉर्क

- 120 Nm

- प्रोसेसिंग टाइप

- Milling & Cut Forming

- Number of Flutes

- 4

- Service Temperature

- Max 400°C

- Maintenance

- Low maintenance required

- Weight

- 320 grams

- Application

- Metal Forming, Automotive, General Engineering

- Life Expectancy

- Long Tool Life

- Tolerance

- ISO Standard Tolerance

- Compatibility

- Universal holders

- Cooling System

- Compatible With Oil-Based Coolants

- Surface Finish

- Polished

- Blade Size

- 4 mm - 20 mm

- Resharpening

- Possible multiple times

- Packaging Type

- Boxed

फà¥à¤°à¥à¤® à¤à¤à¤° Trade Information

- Minimum Order Quantity

- 1 टुकड़ा

- आपूर्ति की क्षमता

- 10000 प्रति महीने

- डिलीवरी का समय

- 1 हफ़्ता

- पैकेजिंग का विवरण

- मानक

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

About फà¥à¤°à¥à¤® à¤à¤à¤°

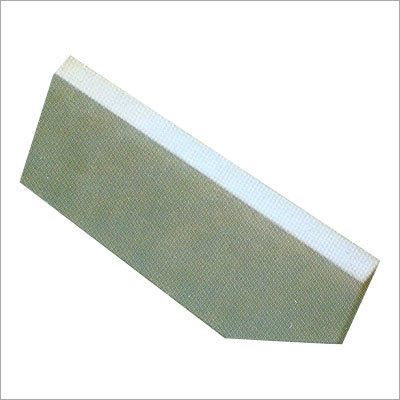

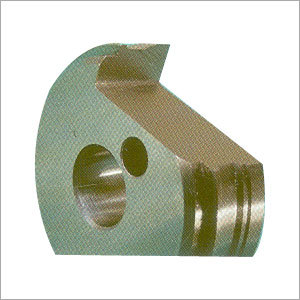

Form Cutters we deal in are functional as the precision cutting tools, which can make the form as the space between two neighboring teeth on a gear. The special method of the cutters is utilized for cutting gear teeth on the milling machine. The template-cutting method of these cutters can assist in guiding the single-point cutter. Form Cutters make use of a cutting tool. These can also be used for the cutting gear teeth on the milling machine. These are the cutting tools, which have the shaped edges.

Precision Cutting For Complex Profiles

Crafted with a polished finish and 4 precisely engineered flutes, the Form Cutter is designed for achieving intricate forms in metals. Its cylindrical shape and profile/form cutter design make it ideal for applications requiring exacting tolerances and high dimensional accuracy. Benefit from its 0.01 mm cutting precision and smooth operation, even under challenging industrial conditions.

Durable Performance & Extended Tool Life

This Form Cutter is made from high-speed steel (HSS) and boasts a Titanium Nitride (TiN) coating, offering exceptional wear resistance and stability at service temperatures up to 400C. The single-layer coating extends operational life, allowing for repeated resharpening, while low maintenance demands reduce downtime and operational costs.

Universal Compatibility and User Convenience

With a diameter of 16 mm and lengths up to 90 mm, this cutter fits standard universal holders and suits both manual and automated CNC milling machines. Users appreciate its compatibility with oil-based coolants and boxed packaging for safe storage and transportation. Ideal for distributors, exporters, and manufacturers, particularly in India, seeking versatility in a single tool.

FAQs of Form Cutter:

Q: How can the Form Cutter be used in both manual and automated operations?

A: The Form Cutters design allows it to be used in traditional manual milling setups as well as modern CNC milling machines, thanks to its universal holder compatibility and precise cutting configuration.Q: What benefits does the Titanium Nitride (TiN) coating provide?

A: The TiN coating increases surface hardness, enhances abrasion resistance, and reduces friction, resulting in improved tool longevity, smoother finishes, and enhanced cutting speeds, particularly when processing metals.Q: When should the cutter be resharpened, and how often can this be done?

A: Resharpening is recommended whenever the cutter shows signs of dullness, reduced precision, or increased cutting effort. The tool is designed for multiple resharpenings, which extends its overall lifespan and performance.Q: Where is the Form Cutter commonly used?

A: It is widely utilized in metal forming, automotive production lines, and general engineering applications, especially where accurate profile forming and high durability are required.Q: What is the maintenance process for this Form Cutter?

A: The tool requires minimal maintenance: routine cleaning after use, periodic inspection for wear, and resharpening when necessary. Using appropriate oil-based coolants further protects and extends the tools service life.Q: How does the cutter ensure accurate and smooth finishing?

A: Precision manufacturing, a polished surface, and strict ISO standard tolerances (0.01 mm) contribute to clean, smooth cuts, while the robust HSS material and TiN coating maintain consistent edge sharpness throughout prolonged use.Q: What are the main advantages of choosing this Form Cutter for industrial applications?

A: Key advantages include high precision, low maintenance, outstanding wear resistance, multiple resharpening potential, and broad compatibility with various machine types and holder systems, making it an economical and reliable choice for professionals.

Price 100 - 20000 आईएनआर/ टुकड़ा

- Minimum Order Quantity

- Supply Ability

- Delivery Time

- Main Domestic Market

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in विशेष उपकरण Category

विशेष थ्रेडिंग और पंचिंग टूल

मूल्य की इकाई : टुकड़ा/टुकड़े

मूल्य या मूल्य सीमा : आईएनआर

माप की इकाई : टुकड़ा/टुकड़े

न्यूनतम आदेश मात्रा : 1

मटेरियल : ,

प्रचालन विधि : Manual or CNC compatible

आयताकार ब्लेड कटर

मूल्य की इकाई : टुकड़ा/टुकड़े

मूल्य या मूल्य सीमा : आईएनआर

माप की इकाई : टुकड़ा/टुकड़े

न्यूनतम आदेश मात्रा : 1

मटेरियल : ,

प्रचालन विधि : Manual

ब्लेड कटर सर्कुलर

मूल्य की इकाई : टुकड़ा/टुकड़े

मूल्य या मूल्य सीमा : आईएनआर

माप की इकाई : टुकड़ा/टुकड़े

न्यूनतम आदेश मात्रा : 1

मटेरियल : ,

प्रचालन विधि : Manual

|

JALDHARA SMALL TOOLS PVT. LTD.

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |