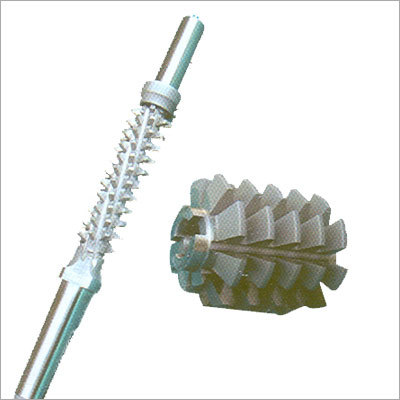

Shank Type Hobs With 2 Teeth Section

Shank Type Hobs With 2 Teeth Section Specification

- Tool Type

- Shank type hob with double section

- Cutter Type

- Gear cutter, involute profile

- Length

- 50 mm to 160 mm

- Machine Type

- Hobbing machine compatible

- Cutting Capacity

- Suited for precision gear cutting

- Features

- High wear resistance, precision grinding, stable performance

- Cutting Accuracy

- Class AA, A, B as per DIN 3968

- Shape

- Cylindrical with 2 teeth section

- Hardness

- 58-63 HRC

- Coating Type

- Optional: TiN, TiAlN, AlCrN, etc.

- Operation Type

- External gear cutting

- Cutting Speed

- Varies with material - typically 20-80 m/min

- Coating

- Uncoated (standard) or as per request

- Operate Method

- Manual and CNC compatible

- Cutting Force

- Optimized for efficient material removal with low vibration

- Material

- High Speed Steel (HSS) / M35 / M2 or as specified

- Diameter

- 8 mm to 40 mm

- Maximum Torque

- Application dependent, designed for stability

- Processing Type

- Gear hobbing

Shank Type Hobs With 2 Teeth Section Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 Week

About Shank Type Hobs With 2 Teeth Section

Shank Type With 2 Teeth Section

Salient attributes:

- Accurate dimensions

- Precision designs

- Resistance against corrosions

- Durability

Product details

| Country of Origin | Made in India |

| Length | Standard |

| Coating | Powder coating |

| Diameter | Standard |

| Brand | Jaldhara Small tool |

| Material | Metal |

| Size | Standard |

High-Performance Gear Cutting

Shank Type Hobs With 2 Teeth Section are engineered for exceptional durability and fine precision in gear manufacturing. Precision ground surfaces, strict tolerances, and dynamic balancing contribute to stable, high-speed operations, making them ideal for automotive, machine tool, and industrial applications. Their advanced materials and customizable configurations enable superior gear cutting performance.

Custom Solutions for Specialized Needs

These hobs offer extensive customization, including module size, helix angles, profiles, and advanced coatings such as TiN, TiAlN, or AlCrN upon request. This adaptability ensures a perfect fit for diverse manufacturing requirements, guaranteeing optimal results for both spur and helical gear production in a range of machine setups.

FAQs of Shank Type Hobs With 2 Teeth Section:

Q: How do Shank Type Hobs With 2 Teeth Section improve gear manufacturing processes?

A: These hobs provide precise involute profiles and maintain strict pitch accuracy, ensuring high-quality gear production. Their rigid integral shank and dynamic balancing minimize vibration, while the capability for multiple regrinds extends their service life and reduces tooling costs.Q: What applications are suited for these double-section hobs?

A: They are ideal for external gear cutting in automotive, industrial, and machine tool sectors, compatible with both CNC and manual hobbing machines. Their versatility and customizable specs support a wide array of gear manufacturing tasks.Q: When should the hobs be reground, and will it affect their accuracy?

A: You should regrind the hobs when cutting performance decreases or wear is apparent. Thanks to precision grinding and material stability, these hobs can be reground multiple times without profile loss, maintaining cutting accuracy throughout their lifespan.Q: Where are these hobs manufactured and supplied from?

A: These shank type hobs are manufactured, distributed, and exported from India. The supplier network ensures availability for both domestic and international customers across gear manufacturing industries.Q: What is the process for customizing the hob to specific gear requirements?

A: Customers can specify size, profile, helix angle, and preferred surface coating. The manufacturer then produces the hob to those exact specifications, ensuring precise compatibility with designated gear cutting tasks and maximizing operational efficiency.Q: What benefits do precision ground hobs with dynamic balancing offer?

A: Precision ground surfaces guarantee high cutting accuracy, while dynamic balancing allows for stable, high-speed operation. This leads to consistent gear quality, extended tool life, and efficient production with low vibration and minimized setup adjustments.

Price 100 - 20000 INR/ Piece

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 Week

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Hobs Category

Worm Wheel Hobs

Price 100 - 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Others, High Speed Steel (HSS), Powder Metallurgy HSS, Carbide

Operate Method : Manual and CNC compatible

Coating : Uncoated, Optional special coatings available

Processing Type : Gear Cutting / Forming

Shank Type Hob

Price 100 - 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Others, High Speed Steel (HSS) / Carbide

Operate Method : Manual or CNC

Coating : TiN (Titanium Nitride)

Processing Type : Gear Hobbing

Ratchet Hob

Price 100 - 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Others, High Speed Steel (HSS)

Operate Method : Manual or attached with machine operation

Coating : Uncoated

Processing Type : Gear Cutting

Accurate Multi Starts

Price 100 - 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Others, High Speed Steel (HSS)

Operate Method : Manual & Machine Operated

Coating : Polished

Processing Type : Precision Turning/Threading

|

JALDHARA SMALL TOOLS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |