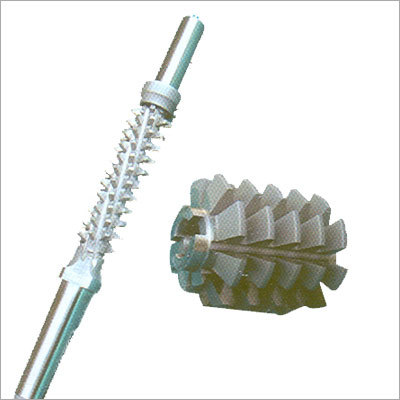

Worm Wheel Hobs

Worm Wheel Hobs Specification

- Coating Type

- Optional: TiN, TiAlN, AlCrN

- Features

- High precision, Wear resistant, Long tool life, ISO Standard compliant

- Cutting Capacity

- Tooth profiles up to Module 20

- Cutting Speed

- Up to 120 m/min (material dependent)

- Machine Type

- Hobbing Machine, CNC Gear Cutting Machine

- Cutting Force

- Optimized for Low Cutting Force

- Operation Type

- High Precision, Continuous Process

- Cutting Accuracy

- DIN 3968 Class A, AA

- Length

- 50 mm to 240 mm

- Tool Type

- Gear Hob, Worm Wheel Hob

- Cutter Type

- Form Cutter, Gear Hob Cutter

- Shape

- Cylindrical, Straight and Helical

- Coating

- Uncoated, Optional special coatings available

- Material

- High Speed Steel (HSS), Powder Metallurgy HSS, Carbide

- Operate Method

- Manual and CNC compatible

- Hardness

- 58-65 HRC

- Diameter

- 20mm to 250mm

- Maximum Torque

- Application dependent

- Processing Type

- Gear Cutting / Forming

Worm Wheel Hobs Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 Week

- Packaging Details

- Standard

- Main Domestic Market

- All India

About Worm Wheel Hobs

Salient attributes:

- Accurate dimensions

- Precision designs

- Resistance against corrosions

- Durability

Product details

| Brand | Jaldhara small tools |

| corrosion resistance | yes |

| I Deal in | new only |

| Industry | Any |

| Size | Standard |

| Country of Origin | Made in India |

Precision-Engineered for Gear Excellence

Worm Wheel Hobs are specifically designed to deliver outstanding performance and reliability in worm gear manufacturing. These hobs cater to a diverse range of module sizes and tooth profiles, whether straight or helical. Their advanced precision and durability make them ideal for both manual and CNC gear cutting machines. Enhanced by high-quality materials and rigorous industry compliance, they offer extended tool life for continuous, high-precision operations.

Versatility Across Multiple Applications

Our hobs are adaptable to both arbor-mounted and shank-type setups, servicing various gear materials including bronze, brass, steel, and cast iron. With support for single, double, or multi-start tooth configurations, they seamlessly integrate into diverse gear production lines. The customizable blade sizes, relief angles, and optional coatings ensure these tools meet unique operational and material requirements with consistent results.

FAQs of Worm Wheel Hobs:

Q: How do I select the appropriate worm wheel hob for a specific gear manufacturing application?

A: Choose a worm wheel hob based on your required module size (0.5 to 20), tooth type (straight or helical), gear material (bronze, brass, steel, or cast iron), and hobbing machine compatibility (manual or CNC). Consider the desired pitch and profile accuracy, relief angle, coating, and mounting type to match your specific process needs.Q: What standards and accuracy levels do these hobs comply with?

A: Our worm wheel hobs conform to renowned industry standards such as DIN, ISO, and AGMA, ensuring universal compatibility. They provide profile accuracy up to DIN AA and pitch accuracy up to class AAA, with cutting accuracy as precise as DIN 3968 Class A or AA for the highest quality gear production.Q: Where are these worm wheel hobs commonly used?

A: They are primarily utilized in worm wheel and gear manufacturing across automotive, industrial machinery, and equipment sectors. Their high precision makes them suitable for use in both large-scale production lines and specialized component manufacturing in India and worldwide.Q: What is the recommended process for using these hobs to maximize tool life and surface finish?

A: Apply external coolant during hobbing to manage heat and prolong tool life. Ensure machines are balanced to at least G1.0 as per ISO 1940, and select proper cutting speeds (up to 120 m/min, depending on material). Optional super polishing can be requested for an ultra-smooth mirror finish.Q: Can I use these hobs on both manual and CNC gear cutting machines?

A: Yes, our worm wheel hobs are designed for seamless operation on both manual hobbing machines and advanced CNC gear cutting equipment, enabling continuous, high-precision processes in varied production environments.Q: What are the key benefits of choosing your worm wheel hobs?

A: Key advantages include long-lasting wear resistance, high precision, versatile application options, adherence to international standards, ready-to-use pre-sharpened condition, and customizable blade dimensions or coatings to meet specific application requirements.

Price 100 - 20000 INR/ Piece

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Hobs Category

Module-D.P-C.P Hobs

Price 100 - 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Corrosion Resistant, Precision Engineered, High Wear Resistance

Machine Type : CNC Hobbing Machine

Cutting Accuracy : 0.05 mm

Maximum Torque : 280 Nm

Fine Pitch Hob

Minimum Order Quantity : 1 Piece

Features : High precision, Wear resistant, Long tool life

Machine Type : Gear Hobbing Machine

Cutting Accuracy : 0.005 mm

Maximum Torque : 150 Nm

Shank Type Hob

Price 100 - 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Wear Resistant, High Precision, Long Service Life

Machine Type : Gear Hobber, CNC Gear Cutting Machine

Cutting Accuracy : DIN 3968 Class AA, A

Maximum Torque : 350 Nm

Multi Start Hobs

Price 100 - 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Features : High durability, accurate profile, suitable for mass production

Machine Type : Gear Hobbing Machine Compatible

Cutting Accuracy : Precision Ground

Maximum Torque : Optimized for Multi Start Gears

|

JALDHARA SMALL TOOLS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |