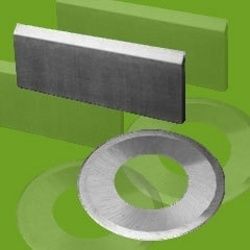

Work Rest Blades

Work Rest Blades Specification

- Features

- Wear Resistant, High Strength, Precision Ground, Customizable Profiles

- Cutting Force

- High Precision, Application-Specific

- Coating Type

- Uncoated / As Required

- Cutting Speed

- Dependent on Application / Grinding Wheel

- Machine Type

- Centerless Grinding Machine

- Length

- Customizable (Typically 50 mm to 1000 mm)

- Tool Type

- Work Rest Blade for Centerless Grinding

- Cutting Accuracy

- Up to 0.005 mm

- Hardness

- Up to 64 HRC (Material Dependent)

- Cutting Capacity

- Application Dependent

- Operate Method

- Mounted / Fixed

- Cutter Type

- Work Rest Blade

- Operation Type

- Centerless Grinding Support

- Shape

- Rectangular / Custom

- Material

- Alloy Steel / Tool Steel / Carbide

- Coating

- Optional (Carbide Tipped / HSS Options)

- Processing Type

- Grinding

Work Rest Blades Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 Week

About Work Rest Blades

Buy from us Work Rest Blades that can be used in various machining and cutting applications to ensure smooth and efficient machining of engineering elements.It is manufactured by our skilled professional engineering standards by using advanced production techniques that result in high uniformity and a smoother surface finish. It is available in various sizes that can be customized as per the customer demands and application areas. Buyers can get Work Rest Blades from our company at a reasonable price range with an assurance of fast and safe delivery.

Product details

| Country of Origin | Made in India |

| Yield Strength | Standard |

| Usage/Application | Industrial |

| Material | HSS |

| Size | Standard |

| Color | Silver |

Superior Precision for Centerless Grinding

Work Rest Blades with a polished edge finish and tolerance up to 0.005 mm deliver high-accuracy profiling for flawless centerless grinding support. Their precisely ground surfaces and customizable shapes ensure consistent workpiece positioning, improving grinding efficiency and product quality.

Built for Long Service Life and Reliability

Manufactured from robust materials such as alloy steel, tool steel, or carbide, these blades are case hardened or nitrided upon request, reaching hardness up to 64 HRC. This reliable construction ensures long service life, even in demanding, high-precision industrial environments.

Versatile Customization for Any Setup

Whether you need custom profiles, specific sizes, material upgrades, or special coating options, these blades can be tailored to fit your grinding system requirements. Supplied with protective packaging, they are ideal for diverse centerless grinding needs across manufacturing, engineering, and tooling industries.

FAQs of Work Rest Blades:

Q: How do Work Rest Blades support centerless grinding operations?

A: Work Rest Blades provide stable and precise support to workpieces during centerless grinding. Their accurate profile and rigid construction help maintain the position and alignment of the part, enabling consistent grinding across batches.Q: What applications are these Work Rest Blades suitable for?

A: These blades are specifically designed for use in centerless grinding machines and are suitable for various industries where tight tolerances, surface quality, and high production efficiency are required.Q: When should I consider customizing the size or profile of a Work Rest Blade?

A: Customization is recommended when your application demands a unique workpiece size, profile specification, or specific material. Custom blades enhance fit, operational accuracy, and grinding performance for non-standard requirements.Q: Where are the Work Rest Blades manufactured and supplied from?

A: We are a distributor, exporter, manufacturer, and supplier based in India, supplying Work Rest Blades worldwide to meet diverse centerless grinding needs.Q: What is the typical process for producing these Work Rest Blades?

A: The blades are manufactured using precision grinding to achieve smooth, polished edges (Ra 0.2 m). They are also case hardened or nitrided if specified, undergo strict quality inspections, and are safely packaged for delivery to ensure performance and protection during transit.Q: How does surface treatment benefit the service life of the blade?

A: Optional treatments like case hardening or nitriding increase the surface hardness (up to 64 HRC), thereby improving wear resistance and extending the blades operational life, especially when used for high-precision or heavy-duty grinding applications.Q: What are the benefits of using high-precision, wear-resistant Work Rest Blades?

A: Precision blades ensure stable workpiece support, improve grinding accuracy, and reduce downtime due to wear. Their robust design and optional coatings further extend service life and optimize performance for demanding centerless grinding environments.

Price 100 - 20000 INR/ Piece

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 Week

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Profile Cutters Category

Chain Sprocket Cutter

Price 100 - 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Cutting Accuracy : 0.03 mm

Hardness : HRC 5565

Cutter Type : Form Cutter

Operate Method : Rotary Cutting

Convex And Concave Cutter

Price 100 - 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Cutting Accuracy : 0.005 mm

Hardness : 5564 HRC

Cutter Type : Form Relief Cutter

Operate Method : Rotary Cutting

Profile Cutters

Price 100 - 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Cutting Accuracy : High Precision (0.1 mm)

Hardness : HRC 5065

Cutter Type : Profile Milling Cutter

Operate Method : Mounted on CNC or Manual Milling Machines

Corner Radius Cutter

Price 100 - 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Cutting Accuracy : 0.01 mm

Hardness : >= 92 HRC

Cutter Type : End Mill (Corner Radius)

Operate Method : Rotary Milling (Spindle)

|

JALDHARA SMALL TOOLS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |