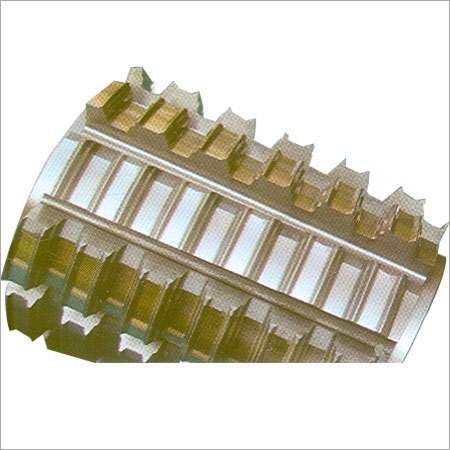

Single Position Hob Multi Thread

Single Position Hob Multi Thread Specification

- Cutting Force

- Low to medium

- Cutting Speed

- 30-50 m/min

- Cutter Type

- Thread Hob Cutter

- Machine Type

- Thread Milling Machine / Gear Hobbing Machine

- Shape

- Cylindrical

- Cutting Accuracy

- 0.01 mm

- Cutting Capacity

- Multi-threaded

- Tool Type

- Single Position Hob

- Material

- High-Speed Steel (HSS)

- Operate Method

- Manual or CNC

- Features

- High precision, long life, multi-thread process in single position

- Length

- 100 mm - 350 mm

- Coating

- TiN (Titanium Nitride)

- Hardness

- 58-62 HRC

- Operation Type

- External Thread Cutting

- Coating Type

- PVD Coating

- Diameter

- 20 mm - 150 mm

- Maximum Torque

- Up to 500 Nm

- Processing Type

- Thread Cutting

Single Position Hob Multi Thread Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 Week

About Single Position Hob Multi Thread

Single Position Hob Multi Thread is accessible with a wide range of teeth cutting. This is apt for different applications such as involute splines, key splines, spur/helical gears, double helical herringbone gears, HTD timer pulleys, worm gears, serrations, ratchet wheels, type hobs, chain sprocket wheels, duplex etc. Single Position Hob Multi Thread has been designed with some special modifications such as generating module or a fixed position with short lead. Its cut is deep and incisive.

Precision and Versatility for Thread Cutting

This Single Position Hob Multi Thread offers exceptional adaptability, supporting a range of thread types and module sizes. Its cylindrical HSS body and custom blade sizing ensure optimal performance for Metric, ACME, Trapezoidal, Worm, and Spindle threads. TiN coating enhances durability and accuracy, making it ideal for multi-thread applications where precision and repeatability are paramount.

Suitable for Demanding Industrial Applications

Designed to meet the rigorous demands of automotive, aerospace, and general industrial machinery, this hob cutter excels in both manual and CNC thread milling or hobbing machines. Its robust construction allows for low to medium cutting force and a maximum torque of up to 500 Nm, while maintaining minimal surface roughness and high dimensional accuracy.

Easy Maintenance and Long Service Life

This precision tool not only supports resharpening but is also housed in a protective plastic box to ensure safe handling during transport and storage. The PVD TiN coating and high-grade HSS material contribute to extended tool life and reduced frequency of tool replacements, making it a cost-effective solution for manufacturers and suppliers.

FAQs of Single Position Hob Multi Thread:

Q: How is the Single Position Hob Multi Thread commonly used in industrial applications?

A: This hob is primarily used for external thread cutting in diverse sectors such as automotive, aerospace, and industrial machinery. Its ability to handle various thread typesMetric, ACME, Trapezoidal, Worm, and Spindlemakes it suitable for manufacturing screws, shafts, and similar components requiring high-precision multi-thread processing.Q: What is the recommended process for maintaining the hobs cutting performance?

A: To maintain optimal cutting performance, regular resharpening is advised. The tool is designed to allow resharpening without compromising accuracy. Using coolant during operation is also recommended, as it helps reduce wear and maintain a surface finish of Ra 0.8 m.Q: When should I use the Single Position Hob Multi Thread over other types of thread cutting tools?

A: This hob should be chosen when high precision, multi-thread capability, and versatility across thread types are required. Its module range of 0.5 to 10 and compatibility with different machines make it especially valuable for operations demanding strict dimensional tolerances and surface quality.Q: Where can this hob be installed, and what machines is it compatible with?

A: The Single Position Hob Multi Thread is compatible with thread milling machines and gear hobbing machines that accept standard ISO holders. Its design accommodates a wide diameter range (20 mm to 150 mm), ensuring adaptability in various production environments.Q: What benefits does the TiN (Titanium Nitride) coating provide?

A: The TiN coating, applied via PVD, significantly increases surface hardness to 5862 HRC, enhances wear resistance, and extends the tools life. It also contributes to achieving tighter tolerances, maintaining cutting speed (3050 m/min), and producing smoother finishes on the threads.Q: How does the custom blade size impact the tools versatility?

A: Custom blade sizing allows the hob to be tailored according to the specific thread type and application, ensuring maximum efficiency and precision regardless of the module or thread standard. This flexibility enhances compatibility across a range of workpiece sizes and designs.

Price 100 - 20000 INR/ Piece

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 Week

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Hobs Category

Sprockets Hob

Price 100 - 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Cutting Accuracy : High Precision

Shape : Cylindrical

Processing Type : Gear Cutting

Machine Type : Hobbing Machine

Multi Start Hobs

Price 100 - 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Cutting Accuracy : Precision Ground

Shape : Cylindrical

Processing Type : Gear Cutting

Machine Type : Gear Hobbing Machine Compatible

Accurate Multi Starts

Price 100 - 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Cutting Accuracy : High Precision

Shape : Round

Processing Type : Precision Turning/Threading

Machine Type : Lathe/Threading Machine

Spline Shaft With Lugs

Price 100 - 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Cutting Accuracy : High Precision

Shape : Cylindrical with lugs

Processing Type : Broaching / Hobbing

Machine Type : CNC / Manual

|

JALDHARA SMALL TOOLS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |