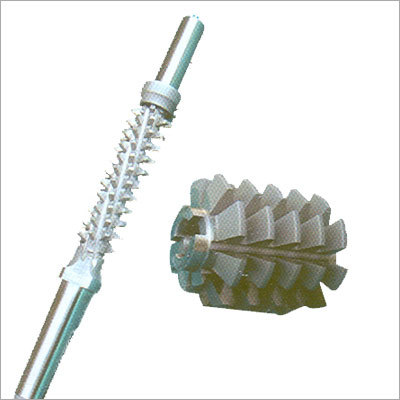

Accurate Multi Starts

Accurate Multi Starts Specification

- Cutting Accuracy

- High Precision

- Features

- Multi Start Threads, High Wear Resistance, Accurate Thread Form

- Operate Method

- Manual & Machine Operated

- Cutter Type

- Thread Cutter

- Coating

- Polished

- Tool Type

- Threading Tool

- Cutting Speed

- High

- Length

- Multiple Lengths Available

- Hardness

- HSS Standard Hardness

- Cutting Capacity

- Varied, Multi Start Capability

- Operation Type

- Threading/Cutting

- Coating Type

- Bright Finish

- Material

- High Speed Steel (HSS)

- Machine Type

- Lathe/Threading Machine

- Cutting Force

- Standard

- Shape

- Round

- Diameter

- Custom Range Available

- Maximum Torque

- Optimized for Performance

- Processing Type

- Precision Turning/Threading

Accurate Multi Starts Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 Week

About Accurate Multi Starts

We offer a wide variety of Multi Start Lead Screws to our clients that are exclusively used as a vital part in several machine types. Our collection of multi start lead screws offers smooth .

Product details

| Country of Origin | Made in India |

| Length | Standard |

| Coating | Powder coating |

| Diameter | Standard |

| Brand | Jaldhara Small tool |

| Material | Metal |

| Size | Standard |

Engineered for Precision and Durability

Our multi-start threading tools combine accurate thread forms with excellent wear resistance and a polished surface. Optimized for both manual and machine-operated processes, they deliver high-precision threading across engineering, automotive, and machine building industries. You benefit from long tool life and consistent results, even under demanding conditions.

Flexible Multi-Start Capability and Custom Sizing

With the flexibility to produce 2, 3, or more start threads, these tools accommodate custom diameters and multiple lengths, supporting complex threading needs. Our manufacturing process ensures each piece meets stringent tolerance requirements, and options for packaging and blade sizes are available as per your specifications.

Corrosion-Resistant and Performance-Oriented Design

Each threading tool features a polished bright finish and is crafted from corrosion-resistant HSS. The standard hardness and high wear resistance guarantee longevity and reliability, backed by an optimized maximum torque for performance and smooth operation in high-speed threading tasks.

FAQs of Accurate Multi Starts:

Q: How do multi-start threading tools improve efficiency in industrial applications?

A: Multi-start threading tools enable the creation of threads with multiple starts (such as 2 or 3), allowing quicker assembly and disassembly. This increases production efficiency and reduces operational time, especially in automotive, engineering, and machine building sectors.Q: What processes are used to manufacture Accurate Multi Start Threading Tools?

A: These tools are manufactured using precision turning and threading, ensuring tight tolerances and accurate thread forms. The use of high-speed steel (HSS) and a polished bright finish further enhances durability and surface quality.Q: When should I choose a multi-start thread over a single-start thread?

A: Multi-start threads are ideal when high linear movement per revolution is required, such as in fasteners or mechanical parts in engineering and automotive sectors. They provide smooth motion and greater load distribution compared to single-start threads.Q: Where can these threading tools be used effectively?

A: Accurate Multi Start Threading Tools are suitable for use in industries like engineering, automotive, and machine building, and can be operated on lathes or threading machines for both manual and automated processes.Q: What are the main benefits of using HSS for these threading tools?

A: High Speed Steel (HSS) offers superior hardness, high wear resistance, and excellent cutting edge retention. These properties ensure consistent performance and longevity, even under high-speed and demanding threading applications.Q: How is corrosion resistance achieved in these tools?

A: Corrosion resistance is achieved through the use of high-quality HSS and a polished bright finish. This combination protects the tools from rust and enhances their durability in various operational environments.

Price 100 - 20000 INR/ Piece

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 Week

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Hobs Category

Worm Wheel Hobs

Price 100 - 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Operate Method : Manual and CNC compatible

Coating : Uncoated, Optional special coatings available

Tool Type : Gear Hob, Worm Wheel Hob

Length : 50 mm to 240 mm

Fine Pitch Hob

Minimum Order Quantity : 1 Piece

Operate Method : Manual and CNC

Coating : TiN Coated

Tool Type : Gear Cutting Hob

Length : Up to 250 mm

Multi Start Hobs

Price 100 - 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Operate Method : Manual or Machine Operated

Coating : Uncoated

Tool Type : Gear Hobs

Length : Standard and Custom Sizes

Single Position Hob Multi Thread

Price 100 - 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Operate Method : Manual or CNC

Coating : TiN (Titanium Nitride)

Tool Type : Single Position Hob

Length : 100 mm 350 mm

|

JALDHARA SMALL TOOLS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |