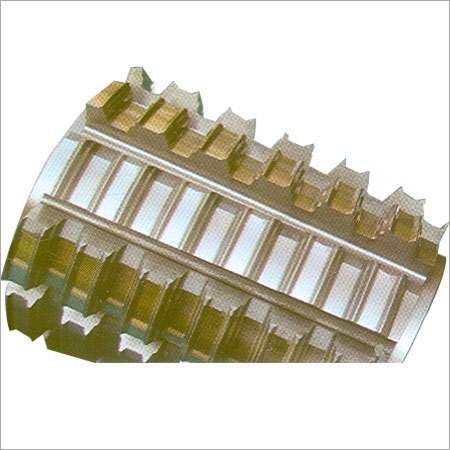

Spline Shaft With Lugs

Spline Shaft With Lugs Specification

- Brooches Type

- Straight Spline

- Cutting Accuracy

- High Precision

- Operate Method

- Machining / Rotational

- Hardness

- 58-62 HRC

- Coating Type

- Corrosion Resistant

- Coating

- Phosphated or Custom as per requirement

- Features

- High Torque, Precision Engineered, Wear Resistant

- Shape

- Cylindrical with lugs

- Tool Type

- Transmission Shaft

- Length

- 100 mm to 1500 mm (customizable)

- Machine Type

- CNC / Manual

- Material

- Alloy Steel (e.g., EN24 / EN353)

- Operation Type

- Power Transmission

- Diameter

- 25 mm to 120 mm (customizable)

- Maximum Torque

- Up to 900 Nm (varies with design)

- Processing Type

- Broaching / Hobbing

Spline Shaft With Lugs Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 Week

- Packaging Details

- Standard

- Main Domestic Market

- All India

About Spline Shaft With Lugs

Features

- Abrasion resistance

- Accurate dimensions

- Rigid construction

- High strength

- Durability

Precision Engineering for Demanding Applications

Spline shafts with lugs are engineered to deliver reliable power transmission and durability in challenging fields including automotive, machinery, and agriculture. Customizable for length, diameter, coating, and specifications, they ensure maximum operational efficiency and performance even under heavy loads. Their robust alloy steel build allows them to withstand demanding environments.

Custom Solutions for Diverse Needs

These shafts are manufactured with versatility in mind, offering a range of customization options including spline count, end type, coating, and overall dimensions to match client specifications. Whether you require a straight or flanged end, specific surface finishes, or unique heat treatment, solutions are tailored for each application as per drawing and requirement.

FAQs of Spline Shaft With Lugs:

Q: How are the spline shafts with lugs manufactured to achieve high precision and durability?

A: Spline shafts with lugs are produced using advanced machining techniques such as CNC/Manual machining, broaching, or hobbing. They undergo case hardening for increased surface strength (58-62 HRC) and are finely ground to precise tolerances (0.02 mm), providing long-lasting performance and reliable operation in heavy-duty environments.Q: What applications are these spline shafts suitable for?

A: These shafts are widely used in automobiles, industrial machinery, and agricultural implements due to their ability to transmit high torque and withstand wear. Their corrosion-resistant coatings and robust material make them suitable for both indoor and outdoor industrial settings.Q: When should I opt for a customized spline shaft design?

A: Customization is recommended when your machinery or project requires non-standard dimensions (diameter 25120 mm, length 1001500 mm), specific spline counts (620), unique end types (plain, threaded, flanged), or specialized coatings. Provide your drawing or specification to receive a solution tailored precisely to your needs.Q: Where are these spline shafts manufactured and can they be exported?

A: Spline shafts with lugs are manufactured in India by experienced exporters, distributors, and suppliers. They can be exported globally with export-quality packaging (wooden boxes or as specified) to ensure safe delivery during transit.Q: What is the typical process for ordering and receiving test certificates?

A: Test certificates can be provided on request to validate material composition, hardness, and dimensional accuracy. During ordering, specify your requirement for certification, and our team will ensure all quality assurances and documentation accompany your shipment.Q: How does lubrication compatibility benefit the usage of these shafts?

A: The shafts are designed for grease or oil lubrication, enabling smooth operation and reducing wear and friction. This compatibility extends the operational life and reliability of the component in power transmission systems.

Price 100 - 20000 INR/ Piece

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Hobs Category

Sprockets Hob

Price 100 - 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Cutting Speed : High

Length : 50 mm to 300 mm

Maximum Torque : Up to 450 Nm

Machine Type : Hobbing Machine

Shank Type Hob

Price 100 - 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Cutting Speed : Up to 80 m/min

Length : Up to 200 mm

Maximum Torque : 350 Nm

Machine Type : Gear Hobber, CNC Gear Cutting Machine

Multi Start Hobs

Price 100 - 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Cutting Speed : High

Length : Standard and Custom Sizes

Maximum Torque : Optimized for Multi Start Gears

Machine Type : Gear Hobbing Machine Compatible

Ratchet Hob

Price 100 - 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Cutting Speed : Standard for ratchet hobs

Length : Customizable length, standard 100300 mm

Maximum Torque : Engineered for hightorque applications

Machine Type : Gear Hobbing Machine

|

JALDHARA SMALL TOOLS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |