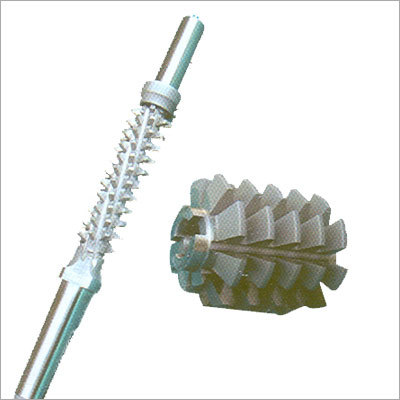

Involute Spline Shaft

Involute Spline Shaft Specification

- Cutting Accuracy

- 0.01 mm

- Cutting Speed

- Varies based on machine and material; typically 100120 m/min for steel

- Operation Type

- Rotational/Translational Routing

- Cutter Type

- Hob Cutter, Rotary Cutter

- Features

- High load-bearing, Precise fitment, Wear resistant, Corrosion resistance option

- Hardness

- HRC 28-55 (depends on material and application)

- Coating Type

- Optional: Black Oxide, Phosphate, Zinc as specified

- Cutting Capacity

- Suitable for heavy-duty power transmission

- Shape

- Cylindrical with external involute splines

- Operate Method

- Mechanical or CNC Machining

- Length

- Customisable, typically 100 mm to 2000 mm

- Tool Type

- Hobbing Tool, Shaping Cutter

- Cutting Force

- High, designed for industrial applications

- Machine Type

- Spline Hobbing/Shaping Machine

- Coating

- Uncoated / As per customer requirement

- Material

- Alloy Steel / Carbon Steel / Stainless Steel (commonly 20MnCr5, 16MnCr5, EN24)

- Diameter

- Custom as per design, typically 10 mm to 120 mm

- Maximum Torque

- Up to 8000 Nm (varies with application and size)

- Processing Type

- External Spline Forming, Hobbing or Shaping

Involute Spline Shaft Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 Week

About Involute Spline Shaft

Involute Spline Shaft is an exclusive series, which is provided with good abrasion-resistance. The shaft is made to facilitate the conduction of rotary movement between two shafts. The provided shaft is made to maintain the arrangement of two mated components. Based on configuration as well as design requirements, the shaft is made to provide performance in several different splines. The shaft is most commonly demanded for the applications, where there is a need of solid lubrication and avoidance of oil contamination.

INVOLUTE SPLINE SHAFT

- It offer client a wide range of INVOLUTE SPLINE SHAFT which are manufactured as per clients requirements.

- We are also specializes in manufacturing of worm shaft.

- INVOLUTE SPLINE SHAFT special sizes which are not mentioned,are manufactured on request according to customer specification

- Apart from INVOLUTE SPLINE SHAFT It also have specialization in manufacturing of standard, non-standard hardened,ground gear,spur gear,helical gear,worm & worm wheel gears,rolling dies, rack cutter, lead screw, hob cutter & serration cutters.

- High efficiency

- Perfect accuracy

- Durable and reliable

- Uniting the Motors and Gearboxes

Precision Engineered for Demanding Applications

Engineered to globally recognized standards, these involute spline shafts are custom-crafted for flawless integration in power transmission systems, gearboxes, and machinery. Advanced manufacturing ensures a precise fit, reliable torque transmission, and superior wear resistance in industrial and automotive sectors. Suitable for both OEM and replacement applications.

Customizable for Every Specification

Every aspect of these spline shaftsfrom number of splines to material, finish, and lengthis tailored to your projects requirements. With flexible end configurations (straight, stepped, or flanged) and optional keyways, they deliver maximum compatibility and bespoke performance for challenging environments.

Quality, Durability, and Expert Support

Produced using high-grade steels and advanced machining methods such as hobbing or shaping, these shafts withstand high loads and harsh conditions. Optional finishes further enhance performance and corrosion resistance. Experienced in distribution, export, and supply from India, solutions are accompanied by responsive support and rigorous quality assurance.

FAQs of Involute Spline Shaft:

Q: How are involute spline shafts manufactured according to customer specifications?

A: Involute spline shafts are produced based on detailed customer drawings and international standards like DIN 5480, ISO 4156, and ANSI B92.1. The manufacturing process involves precision hobbing or shaping using CNC or mechanical machines, ensuring the exact number of splines, module (16), diameter, length, and end configuration. Optional keyways and finishing treatments can also be incorporated as per requirements.Q: What materials and surface finishes are available for these spline shafts?

A: Common material options include alloy steel (20MnCr5, 16MnCr5), EN24, carbon steel, and stainless steel. Surface finishes are customizable from Ra 0.8 to 3.2 m. You can also specify additional coatings (like black oxide, phosphate, or zinc) and heat treatments such as case or induction hardening to optimize wear resistance and durability.Q: When should I opt for optional features like keyways or protective coatings?

A: Keyways are recommended when the shaft needs to transmit power with additional torque security or requires a specific fit with mating components. Protective coatings are advisable if the shaft will operate in corrosive environments or requires enhanced longevity. Both options can be selected during the ordering process based on your applications needs.Q: Where are these involute spline shafts typically used?

A: These shafts are extensively used in automotive transmissions, industrial gearboxes, heavy machinery, and various precision power transmission assemblies. Their high load-bearing capacity and precise tolerances make them ideal for demanding operational settings where reliability and accurate engagement are crucial.Q: What is the process for ordering custom spline shafts, and what is the MOQ?

A: Ordering involves submitting your technical drawings and specifications for review. Manufacturing tolerances, features, and quantities are then discussed; minimum order quantity (MOQ) is determined per agreement, with flexible packaging options like corrugated boxes or wooden crates to suit shipping and storage needs.Q: How does using an involute spline shaft benefit my application?

A: Using a high-quality involute spline shaft ensures precise torque transmission, a secure fit, and resistance to wear and corrosion. Custom engineering allows integration into existing systems with minimal modifications, resulting in improved efficiency, reduced downtime, and enhanced equipment reliability.

Price 100 - 20000 INR/ Piece

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 Week

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Hobs Category

Special Profile Hob

Price 100 - 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Coating : TiN / TiAlN / Customized

Material : Others, HighSpeed Steel (HSS), Carbide

Processing Type : Hobbing, Gear cutting

Machine Type : Gear Hobbing Machines

Worm Wheel Hobs

Price 100 - 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Coating : Uncoated, Optional special coatings available

Material : Others, High Speed Steel (HSS), Powder Metallurgy HSS, Carbide

Processing Type : Gear Cutting / Forming

Machine Type : Hobbing Machine, CNC Gear Cutting Machine

Shank Type Hob

Price 100 - 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Coating : TiN (Titanium Nitride)

Material : Others, High Speed Steel (HSS) / Carbide

Processing Type : Gear Hobbing

Machine Type : Gear Hobber, CNC Gear Cutting Machine

Accurate Multi Starts

Price 100 - 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Coating : Polished

Material : Others, High Speed Steel (HSS)

Processing Type : Precision Turning/Threading

Machine Type : Lathe/Threading Machine

|

JALDHARA SMALL TOOLS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |