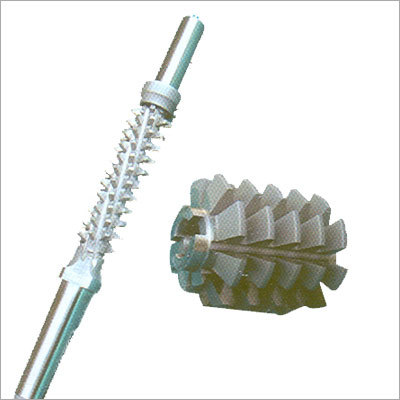

Timing Belt Pulley

Timing Belt Pulley Specification

- Coating

- Uncoated

- Length

- 25 mm

- Material

- Aluminum Alloy

- Hardness

- High

- Tool Type

- Timing Belt Pulley

- Operate Method

- Mechanically Operated

- Shape

- Round

- Machine Type

- Transmission Component

- Cutting Accuracy

- High Precision

- Operation Type

- Mechanical

- Features

- Corrosion resistance, High wear resistance, Silent operation

- Diameter

- 75 mm

- Maximum Torque

- 120 Nm

- Processing Type

- CNC Machined

- Temperature Range

- -20°C to 120°C

- Bore Size

- 20 mm

- Packaging Type

- Boxed

- Pitch

- 5 mm

- Application

- Industrial Automation, Conveyor Systems, Robotics

- Color

- Silver

- Surface Finish

- Smooth

- Number of Teeth

- 32

- Standards

- ISO 13050 Compliant

- Weight

- 0.29 kg

- Hub Type

- Single Hub

- Mounting Type

- Set Screw

Timing Belt Pulley Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 Week

About Timing Belt Pulley

- M X L

- XL

- L

- X H

- H

- X X H

- AT-5

- T-5

- T-2.5

- T-10

- T-20

- H T D

- S-8

- S - 14 M

- type in class AA, A, B & C

Product details

|

Country of Origin |

Made in India |

|

Length |

Standard |

|

Coating |

Powder coating |

|

Diameter |

Standard |

|

Material |

Metal |

|

Size |

Standard |

High-Precision Aluminum Timing Pulley

Manufactured using CNC machining, this timing belt pulley provides exceptional accuracy and durability. Its lightweight aluminum alloy construction assures strong performance while keeping rotational inertia low, making it ideal for high-speed, precision-driven tasks. The high hardness and wear resistance ensure long service life in demanding environments.

Reliable and Versatile Application

Designed for seamless integration in industrial automation, conveyor systems, and robotics, this pulley supports a broad temperature range from -20C to 120C. Whether its high-frequency tasks or extended operation, users experience silent running, minimized maintenance, and optimal torque transmission.

FAQs of Timing Belt Pulley:

Q: How should the Timing Belt Pulley be mounted for secure operation?

A: The pulley is installed using a set screw mounting method. This ensures firm attachment to the shaft, preventing slippage or misalignment during mechanical operations.Q: What are the advantages of the high precision cutting and CNC machining?

A: High precision cutting and CNC machining deliver consistent dimensional accuracy, improved concentricity, and enhanced operational efficiency, especially crucial when timing synchronization and minimal vibration are required.Q: When is this Timing Belt Pulley most beneficial for industrial machinery?

A: The pulley offers optimal benefits in applications that demand reliable torque transfer, silent operation, and durable performance, such as conveyor systems, automated manufacturing lines, and robotic arms operating within the -20C to 120C temperature range.Q: Where can the Timing Belt Pulley be sourced in India?

A: This timing belt pulley is available through established distributors, exporters, manufacturers, and suppliers across India, typically provided in boxed packaging for safe transport.Q: What processes ensure the pulleys high wear and corrosion resistance?

A: The use of high-hardness aluminum alloy and a smooth, uncoated finish, combined with advanced CNC machining, ensures excellent resistance to wear and corrosion, even under continuous mechanical loads.Q: How does the mechanical operation method of this pulley enhance system performance?

A: Being mechanically operated, the pulley delivers dependable power transfer with minimal noise and vibration, enhancing system stability and reducing downtime for maintenance.

Price 20000 INR/ Piece

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 Week

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Hobs Category

Sprockets Hob

Price 100 - 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Operation Type : Other, Continuous/Indexing

Features : Wearresistant, precise profiling, heat treated

Maximum Torque : Up to 450 Nm

Cutting Accuracy : High Precision

Worm Wheel Hobs

Price 100 - 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Operation Type : Other, High Precision, Continuous Process

Features : High precision, Wear resistant, Long tool life, ISO Standard compliant

Maximum Torque : Application dependent

Cutting Accuracy : DIN 3968 Class A, AA

Shank Type Hobs With 2 Teeth Section

Price 100 - 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Operation Type : Other, External gear cutting

Features : High wear resistance, precision grinding, stable performance

Maximum Torque : Application dependent, designed for stability

Cutting Accuracy : Class AA, A, B as per DIN 3968

Accurate Multi Starts

Price 100 - 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Operation Type : Other, Threading/Cutting

Features : Multi Start Threads, High Wear Resistance, Accurate Thread Form

Maximum Torque : Optimized for Performance

Cutting Accuracy : High Precision

|

JALDHARA SMALL TOOLS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |